Manufacturing / Finishing

> Automated and semi-automated coil winding services

> SMT line

> Precision hand assembly (Cell Manufacturing)

> Soldering procedures (automated and by hand using skilled,

certified operators)

> Molding capabilities:

- Automated overmolding (TOWA),

- conventional molding

- Injection molding

> Custom lead forming & laser marking

> Dedicated in-house tool room for tooling and maintenance

> SMT line

> Precision hand assembly (Cell Manufacturing)

> Soldering procedures (automated and by hand using skilled,

certified operators)

> Molding capabilities:

- Automated overmolding (TOWA),

- conventional molding

- Injection molding

> Custom lead forming & laser marking

> Dedicated in-house tool room for tooling and maintenance

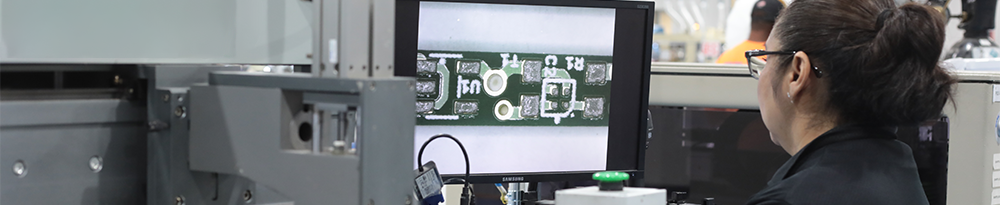

Quality Management, Testing & Inspection

> In-line inspection performed by specially certified personnel

> Parametric electrical testing

> Comprehensive failure analysis services, including:

- Electrical testing

- Cross-sectioning

- X-ray inspection

- Chemical analysis

- Microscopic inspection

- Helium leak testing

- Material element analysis

> Parametric electrical testing

> Comprehensive failure analysis services, including:

- Electrical testing

- Cross-sectioning

- X-ray inspection

- Chemical analysis

- Microscopic inspection

- Helium leak testing

- Material element analysis

Inventory management, storage & tracking

> Kanban inventory management system

> Temperature-controlled storage for sensitive materials

> Full and smart traceability with integrated bar code tracking

> Temperature-controlled storage for sensitive materials

> Full and smart traceability with integrated bar code tracking

Shipping

> Specialized import/export services, including customs documentation, regulatory compliance, and logistics coordination for seamless international shipping

Professional Services

> Integrated design and manufacturing engineering support with a strong focus on customer collaboration throughout the product lifecycle

> End-to-end operations including supply chain management, strategic planning, procurement, and human resources coordination

> End-to-end operations including supply chain management, strategic planning, procurement, and human resources coordination

Manufacturing / Finishing

> Automated and semi-automated coil winding services

> SMT line

> Precision hand assembly (Cell Manufacturing)

> Soldering procedures (automated and manual by skilled, certified operators)

> Molding capabilities:

- Automated overmolding (TOWA),

- conventional molding

- Injection molding

> Custom lead forming & laser marking

> Dedicated in-house tool room for tooling and maintenance

> SMT line

> Precision hand assembly (Cell Manufacturing)

> Soldering procedures (automated and manual by skilled, certified operators)

> Molding capabilities:

- Automated overmolding (TOWA),

- conventional molding

- Injection molding

> Custom lead forming & laser marking

> Dedicated in-house tool room for tooling and maintenance

Quality Management, Testing & Inspection

> In-line inspection performed by specially certified personnel

> Parametric electrical testing

> Comprehensive failure analysis services, including:

- Electrical testing

- Cross-sectioning

- X-ray inspection

- Chemical analysis

- Microscopic inspection

- Helium leak testing

- Material element analysis

> Parametric electrical testing

> Comprehensive failure analysis services, including:

- Electrical testing

- Cross-sectioning

- X-ray inspection

- Chemical analysis

- Microscopic inspection

- Helium leak testing

- Material element analysis

Inventory management, storage & tracking

> Kanban inventory management system

> Temperature-controlled storage for sensitive materials

> Full and smart traceability with integrated bar code tracking

> Temperature-controlled storage for sensitive materials

> Full and smart traceability with integrated bar code tracking

Shipping

> Specialized import/export services, including customs documentation, regulatory compliance, and logistics coordination for seamless international shipping

Professional Services

> Integrated design and manufacturing engineering support with a strong focus on customer collaboration throughout the product lifecycle

> End-to-end operations including supply chain management, strategic planning, procurement, and human resources coordination

> End-to-end operations including supply chain management, strategic planning, procurement, and human resources coordination

Manufacturing / Finishing

> Automated and semi-automated coil winding services

> SMT line

> Precision hand assembly (Cell Manufacturing)

> Soldering procedures (automated and manual by skilled, certified operators)

> Molding capabilities:

- Automated overmolding (TOWA),

- conventional molding

- Injection molding

> Custom lead forming & laser marking

> Dedicated in-house tool room for tooling and maintenance

> SMT line

> Precision hand assembly (Cell Manufacturing)

> Soldering procedures (automated and manual by skilled, certified operators)

> Molding capabilities:

- Automated overmolding (TOWA),

- conventional molding

- Injection molding

> Custom lead forming & laser marking

> Dedicated in-house tool room for tooling and maintenance

Quality Management, Testing & Inspection

> In-line inspection performed by specially certified personnel

> Parametric electrical testing

> Comprehensive failure analysis services, including:

- Electrical testing

- Cross-sectioning

- X-ray inspection

- Chemical analysis

- Microscopic inspection

- Helium leak testing

- Material element analysis

> Parametric electrical testing

> Comprehensive failure analysis services, including:

- Electrical testing

- Cross-sectioning

- X-ray inspection

- Chemical analysis

- Microscopic inspection

- Helium leak testing

- Material element analysis

Inventory management, storage & tracking

> Kanban inventory management system

> Temperature-controlled storage for sensitive materials

> Full and smart traceability with integrated bar code tracking

> Temperature-controlled storage for sensitive materials

> Full and smart traceability with integrated bar code tracking

Shipping

> Specialized import/export services, including customs documentation, regulatory compliance, and logistics coordination for seamless international shipping

Professional Services

> Integrated design and manufacturing engineering support with a strong focus on customer collaboration throughout the product lifecycle

> End-to-end operations including supply chain management, strategic planning, procurement, and human resources coordination

> End-to-end operations including supply chain management, strategic planning, procurement, and human resources coordination

Manufacturing / Finishing

> Automated and semi-automated coil winding services

> SMT line

> Precision hand assembly (Cell Manufacturing)

> Soldering procedures (automated and manual by skilled, certified operators)

> Molding capabilities:

- Automated overmolding (TOWA),

- conventional molding

- Injection molding

> Custom lead forming & laser marking

> Dedicated in-house tool room for tooling and maintenance

> SMT line

> Precision hand assembly (Cell Manufacturing)

> Soldering procedures (automated and manual by skilled, certified operators)

> Molding capabilities:

- Automated overmolding (TOWA),

- conventional molding

- Injection molding

> Custom lead forming & laser marking

> Dedicated in-house tool room for tooling and maintenance

Quality Management, Testing & Inspection

>In-line inspection performed by specially certified personnel

> Parametric electrical testing

> Comprehensive failure analysis services, including:

- Electrical testing

- Cross-sectioning

- X-ray inspection

- Chemical analysis

- Microscopic inspection

- Helium leak testing

- Material element analysis

> Parametric electrical testing

> Comprehensive failure analysis services, including:

- Electrical testing

- Cross-sectioning

- X-ray inspection

- Chemical analysis

- Microscopic inspection

- Helium leak testing

- Material element analysis

Inventory management, storage & tracking

> Kanban inventory management system

> Temperature-controlled storage for sensitive materials

> Full and smart traceability with integrated bar code tracking

> Temperature-controlled storage for sensitive materials

> Full and smart traceability with integrated bar code tracking

Shipping

> Specialized import/export services, including customs documentation, regulatory compliance, and logistics coordination for seamless international shipping

Professional Services

> Integrated design and manufacturing engineering support with a strong focus on customer collaboration throughout the product lifecycle

> End-to-end operations including supply chain management, strategic planning, procurement, and human resources coordination

> End-to-end operations including supply chain management, strategic planning, procurement, and human resources coordination